Product

WT 5921-100T1 Thermal Gel

WT 5921-100T1is a paste-like material formulated using silicone resin as the base, combined with thermally conductive fillers and additives in specific proportions. Processed through controlled techniques, it is also known as Thermal Conductive Putty

▶ Product Features

● High thermal conductivity, low thermal resistance

● Strong deformability, easy to adapt to product designs with large changes in thickness requirements

● Inherent tackiness, eliminating the need for adhesive products that do not enhance thermal performance to improve adhesion

● Excellent high temperature resistance, excellent weather resistance, radiation resistance and excellent dielectric properties

● Excellent chemical and mechanical stability

● No settling, stored at room temperature, convenient storage

● Suitable for filling irregular gaps

● Can be reworked and reused to reduce waste

● No chemical reaction required

● It has extrusion fluidity and is suitable for dispensing process

▶ Performance description

(WT 5921-100T1) Product Specifications | |||

NO. | Inspection project | Performance | Test standard |

1 | Appearance | Grey-White | Visual |

2 | Oil Exudation Rate (150℃*48H) | <0.01 | NA |

3 | Density (g/cm³) | 2.6 | ASTM D792 |

4 | Viscosity(mPa.s) | 254 000 | GB-T 15357 |

5 | Extrusion (g/min) | 125 | 30cc 2.54mm needle @90psi |

6 | Thermal Conductivity(W/(m·K)) | 9.5 | ASTM D5470 |

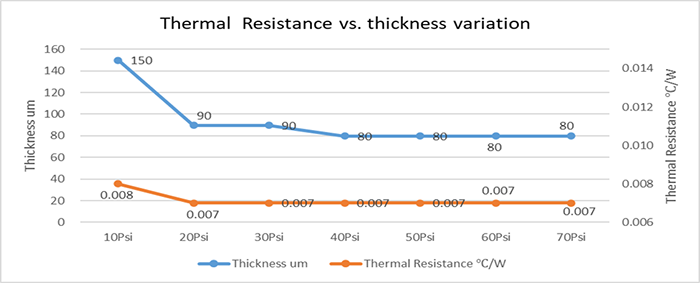

7 | minimum thermal resistance (℃/W)@40PSI | 0.007 | ASTM D5470 |

8 | Thermal impedance (℃*in²/W) | 0.007 | ASTM D5470 |

9 | Thermal impedance(℃*cm²) | 0.045 | ASTM D5470 |

10 | low molecular weight siloxane content(D4-D10)(ppm) | ﹤200 | WT&REACH |

11 | minimum bonding thickness(μm) | 25 | WT Standard |

12 | Dielectric strength(V/mm)50mA | <200 | ASTM D149 |

13 | Volume resistivity(Ω·cm) | ≧1.0×1012 | ASTM D257 |

14 | Temperature range(℃) | -50~200 | NA |

15 | Flame retardant rating | V-0 | UL 94 |

▶ Thickness vs. Thermal Resistance Curve:

▶ Applications area

● Communication equipments

● Automobile electronic controllers

● Power supplies and semiconductors

● Memory and power modules

● Microprocessor/graphics processors

● Panel monitors, computers

● Consumer electronics

▶ Packaging and storage

● Syringe Packaging or Other Packaging Types

● Store at room temperature in a cool, dry place. Shelf life: 12 months

▶ Application method:

1. Pneumatic dispensing

2. Programmed Automated Dispensing

The above is for reference only Final process validation must align with actual application specifications and material behavior.