Product

WTTPUTTY WT 5903-100S

WT 5903-100S Thermal conductive material is sheet shaped and can be pressed to a minimum of 160-180(um), to reduce interfacial thermal resistance and increase thermal conductivity rate.

Typical Application

● High end equipment and automotive electronic cooling and heating components, such as electronic devices, semiconductor memory devices, etc

● General-purpose inverter, Medical equipments, Digital Signal Controllers

● Automotive electronics, such as on-board cameras, motor control units, automotive navigation, automotive lighting (LED)

● Laser HUD light source

● Consumer microelectronics and hand held electronic device(like mobile phone, computer, etc)

● Base station, IGBT modules

Parameter Index

Index | Test Standard | Data |

Color | / | Grey |

Thickness (mm) | ASTM D374 | 0.5-5.0 |

Thermal conductivity (W/(m·K)) | ASTM D5470 | 10.0 |

Thermal resistance (℃/W) | ASTM D5470 | 0.051 |

Volume resistivity (Ω·cm) | ASTM D257 | 1.0×1011 |

Density (g/cm³) | ASTM D792 | 3.6 |

Breakdown voltage (kV/mm) | ASTM D149 | >7 |

Needle penetration(0.1mm) | GB/T4509 | 35 |

Flame retardant rating | UL94 | V-0 |

Minimum compression BLT(μm) | / | 160 |

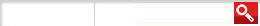

1.0mm Compression Curves under Different Pressure

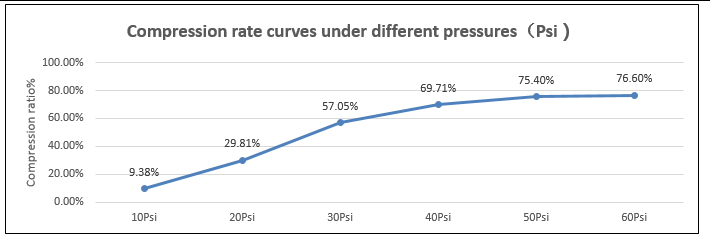

High Temperature Limit Compression Test

Test results:

After

being compressed by 10% and 20% in the limit position and subjected to a

horizontal and vertical heating test at 125 degrees Celsius for 1 hour,

the shape of the product after compression (horizontal and vertical

directions) was basically

the same, and there was no flow or vertical flow phenomenon (horizontal

and vertical directions) at a high temperature of 125 degrees Celsius

for 1 hour.

Function and Characteristics

● Easy to use, easy to remove, good insulation performance, and good rebound performance

● Excellent flexibility: can be perfectly embed in uneven interface

● Excellent flame performance: meet UL94-V0 level

● RoHS, REACH comliance

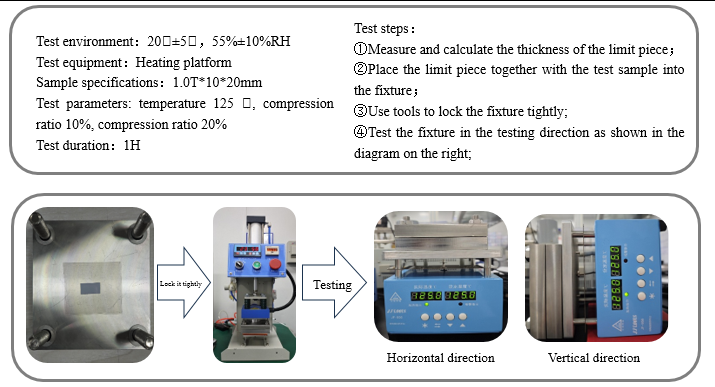

Dimensions

Remarks

For the data sheet, Waermtimo reserves the right to final modification.